Our leisurely daysail out of Christmas Cove started out smoothly. Kory and Jim raised the mainsail and unfurled the Screecher, and the 12-15 knot winds got us flying between 8-9 knots. It was exciting!

But then, the unexpected happened. What we didn’t know is that as soon as we rounded the leeward side of the island and were exposed to the open sea, the swells would increase and the wind gusts would became much higher and more variable than predicted.

Pop gusts of wind started banging the sail furiously. The Screecher is designed to withstand apparent winds up to 15 knots, but these random bursts were so strong and put so much stress on the sail that we knew it was time to furl it in. Unfortunately, before we could do so, a strong surge of wind came upon us and put so much instant force on the Screecher that it broke the loop where the tack connects to the furling system. Once that happened, the bottom of the sail began riding up the furling cable. And since the tack of the sail was no longer connected to the furling system, it made it impossible to bring in the sail. Only the top would wind up, leaving the bottom flailing in the wind. Kory tried to hand-furl the bottom portion as much as possible, but the center would not furl. Our attempts at hand-furling the sail were met with limited success.

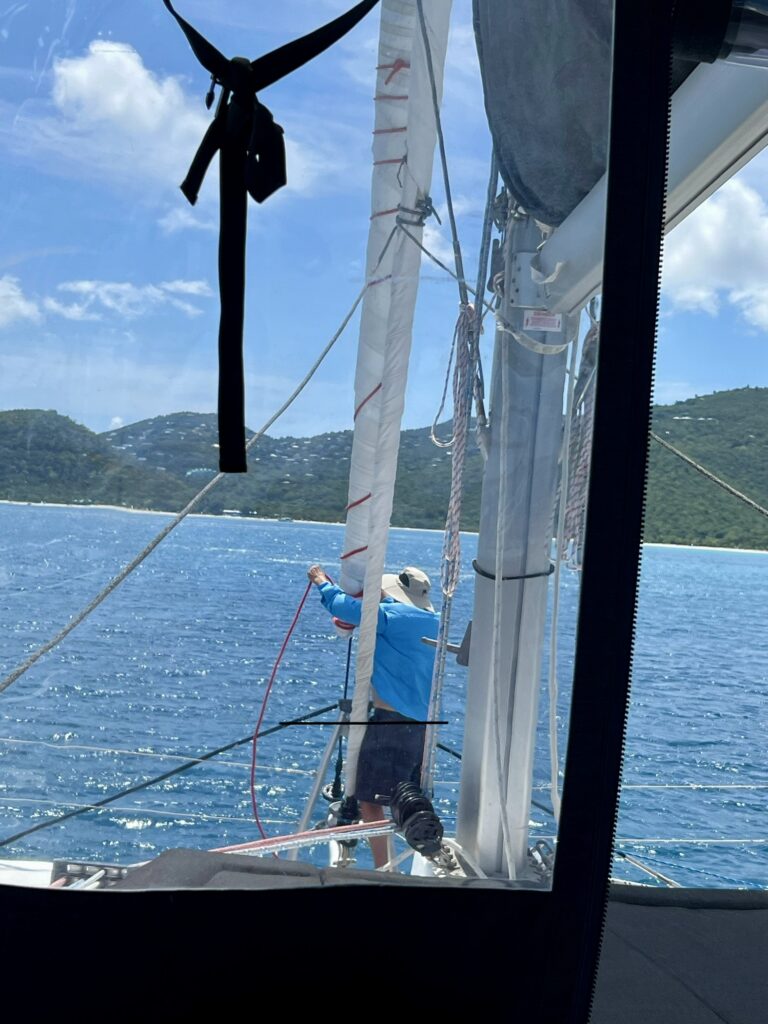

Given the high winds, the partly furled center section began to flail wildly and unfurl more and more. We were afraid of it wrapping around the shroud. Our only course of action was to drop the sail as quickly as possible to get it under control. Since the winds were picking up, and the swells were quite large, we sought protection in St. Thomas’ Megan’s Bay, about 20 minutes away, before attempting to lower the sail. We were thankful for the calm waters in the bay, but the wind was still gusting powerfully, leaving us with another challenge on hand.

As soon as we got inside the bay, we anchored as quickly as possible in order to focus solely on the sail issue without having to worry about steering the boat. We loosened the halyard tension and began lowering the sail. Then we disconnected the furling system from the Spinnaker pole (which turned out to be our big mistake). The plan was to grab the furling drum, walk it toward the back of the boat, and then lay the rest of the sail down on the weather deck. In the process, however, a strong gust of wind seized the center section of the sail, lifted the whole thing with the furling drum, and swung it wildly to the back of the boat on a 45 degree angle. This entire, bulky sail was flailing untamed, and we knew if we didn’t do something quickly, the heavy metal furling drum would eventually smash into our solar arch and crash our solar panels. So we had to act quickly.

We made the split second decision to release the halyard completely and let the sail fall into the sea at the stern of the boat in hopes that we could finally arrest it that way. Praise the Lord, that worked! We breathed sighs of relief and were so thankful that no damage was done to the boat. From there, we each picked up a portion of the sail and began dragging it to the bow of the boat along the deck. We let it dry out and hand-furled it as much as possible before folding it into our sail bag.

The sail was all ready to deliver to a sail shop for repair. We were thankful that St. Martin was our next scheduled stop because this island has multitudes of sail shops, chandleries, and marine stores — just what we needed at this time.

Once in Sint Maarten (the Dutch side of the island), we carried the heavy sail from the bow of the boat to the stern and were able to load it into the dinghy. Kory took it to Tropical Sail Loft inside the lagoon. The shop is right off of the water, so it was easy to dinghy up to the dock and unload it. The sail shop is in a loft on the upper floor of a warehouse building, so the sailmakers use a crane to hoist the sail to the top level. There is plenty of open space in the loft for them to lay out the entire sail, inspect it, and get their work done. Even with a backlog, it only took them one week to get our sail fixed and the total price was $85! Now, that’ an incredible price, which we were happy to pay, for a job well done!

Once we got the sail back on the boat, Ken from Bistari came over to Hope and helped Kory and I hoist it back up. Even on a windy day, we got it lifted up by the electric winch, wrapped, and secured, in about 15 minutes. Our sail is now standing tall, as good as new, and ready to sail again!

So what lessons did we learn that we can share with others?

- Reef early and reef often.

- Drop the sail from top to bottom and disconnect the furling drum last.

- If you have to disconnect the furling drum first, tie it off to a cleat or lifeline so it can’t escape in the wind if a gust comes upon it.

- Use gloves if handling a line in any kind of wind to avoid hand injuries.

- Never step on a line to hold it down. It could wrap around your foot or ankle in an instant and pull you with it. The wind is much more powerful than you are!

- Be willing to allow an uncontrolled sail to drop in the water rather than damage the boat.

- Stay calm, work together as a team, and remember that it’s just a tangible item. Your safety matters most.